Flomac progressive cavity pumps have a wide range of application ranging from chemicals, food product, petroleum, wastewater sludge and high viscosity fluids. Progressive cavity pumps have served a wide variety of industries such as wastewater treatment, chemical industry, pulp and paper, oil and gas and many others. Flomac progressive cavity pumps are made for:

- Liquid with solid content up to 45%

- Viscosities up to 1,000,000 cps

- Fibers

- Shear stress sensible liquids

- Conveying mixture of solid-liquids and gases

Advantages of using Flomac Progressive Cavity Pump:

- Volumetric efficiency up to 96%, mechanical efficiency of up to 70–80%

- Pulsation free and suitable for dosing application

- Suction height up to 8 meters

- Robust and simple design with easy maintenance without any special tooling

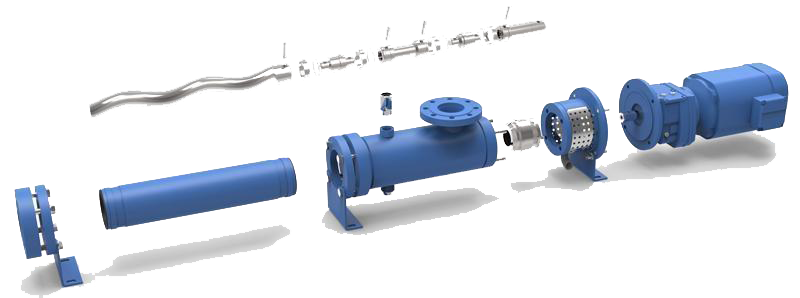

Structure of Flomac PC Pump

Rotor:

Varying rotor geometries and surface material to suit each application needs.

Stator:

Various elastomer material: NBR, EPDM, Viton, PTFE etc.

Joint:

Universal cross joint for stronger and robust connection.

Joint seal:

Reliable and robust design for longer lasting performance .

Shaft seal:

Wide list of seal selection from gland packing to mechanical seal with flushing plans etc.

Driver:

Proven quality of gear motors manufacturers