Emission norms are becoming more and more stringent in our country and hence one of the most vital factors for complying with the stipulated emission norms is selecting appropriate Air Pollution Control System (APCS). But gone are the days when the decision makers of the production unit would think of compliance only, as today, the dynamics of managing the plant has completely changed owing to frequent revision of emission norms as well as challenges in staying profitable.

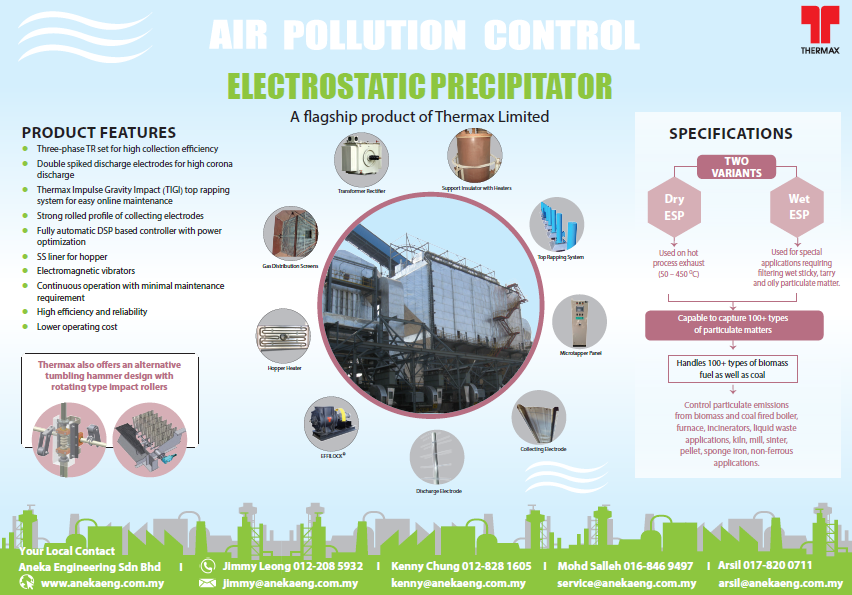

Electrostatic Precipitator (ESP) is a flagship product of Thermax APC business. With more than 2000 ESPs are working successfully across the globe in various industries including power, cement, steel, fertilizers, pulp & paper, textiles, chemical and biomass boiler. Thermax ESP has associated with many leading technologies to provide high efficiency and safety system